Radial Chip Thinning Calculator

Always use caution and best judgement when applying updated speedsfeeds. CIRCLE INTERPOLATION MILLING CALCULATOR.

Chip Thinning Calculators And Formulas Machining Doctor

Drilling cut time SFM calculator 7.

Radial chip thinning calculator. Milling by the maximal chip thickness for the tool. Radial engagement feed rate adjustment calculations to maximize your productivity. ADJUSTED FEEDRATE CHIP THINNING CALCULATOR.

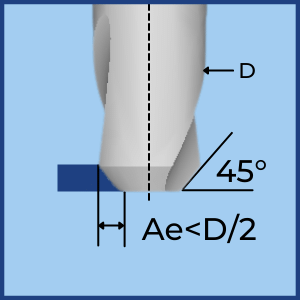

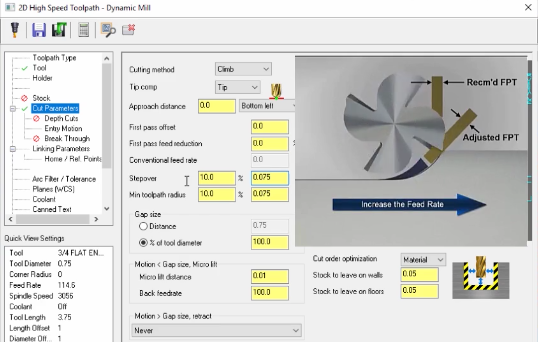

Small axial depth of cut and fast feed rates ie. Small axial depth of cut and fast feed rates I tried the Iscar chip thinning calculator referred to in a previous post and it wont let me enter an axial depth of cut larger than the bull mill radius. If using HSMHEM techniques use chip thinning calculator to adjust feed rate based on Width of Cut.

Surface finish calculators for turning milling 8. The shop wants to realize a chip thickness of 002 CLPT. Drill point length calculator 6.

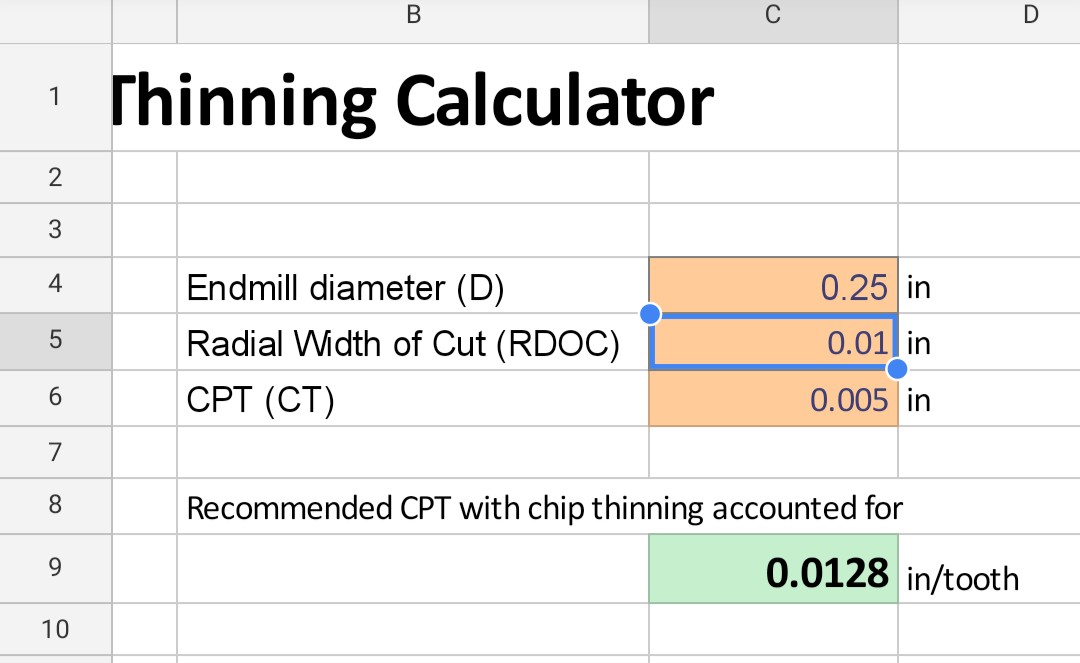

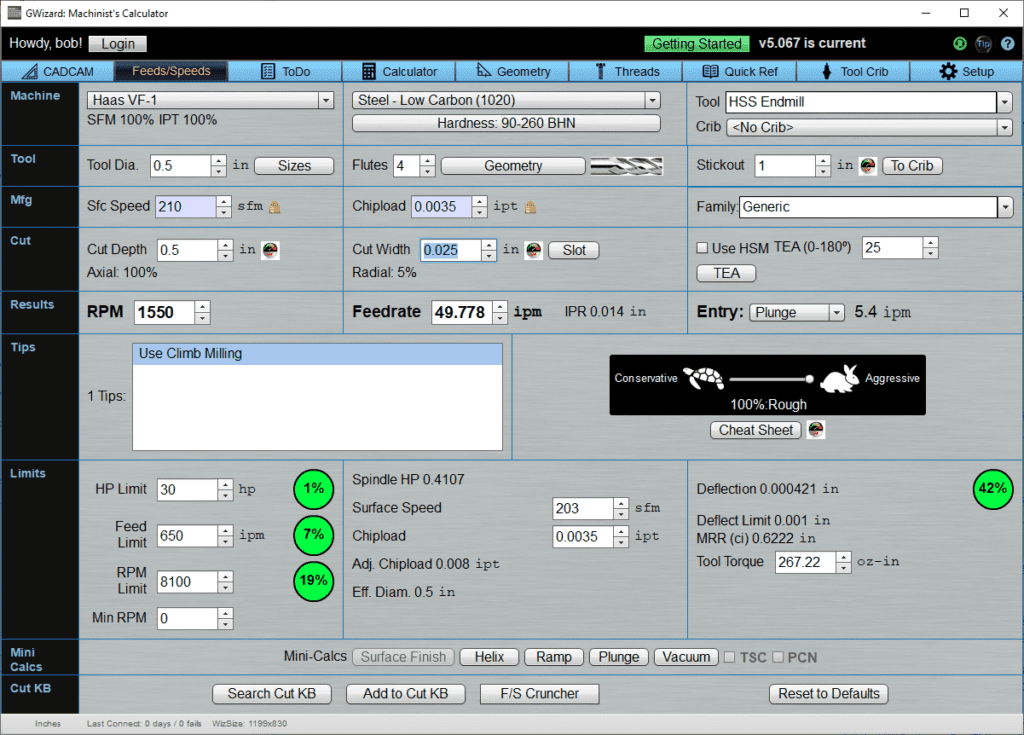

Use this Chip Thinning Calculator Wizard to calculate the RPM IPM MMPM of the milling tool by using Straight InternalExternal in Inch or Metric. SFMRPM can typically be increased when decreasing Radial WOC. Though discussions of radial chip thinning are nothing new the ability to predictably control the maximum thick-ness of a chip during roughing operations very much is.

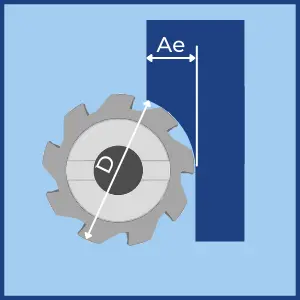

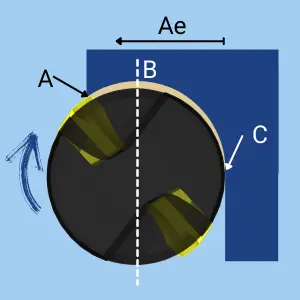

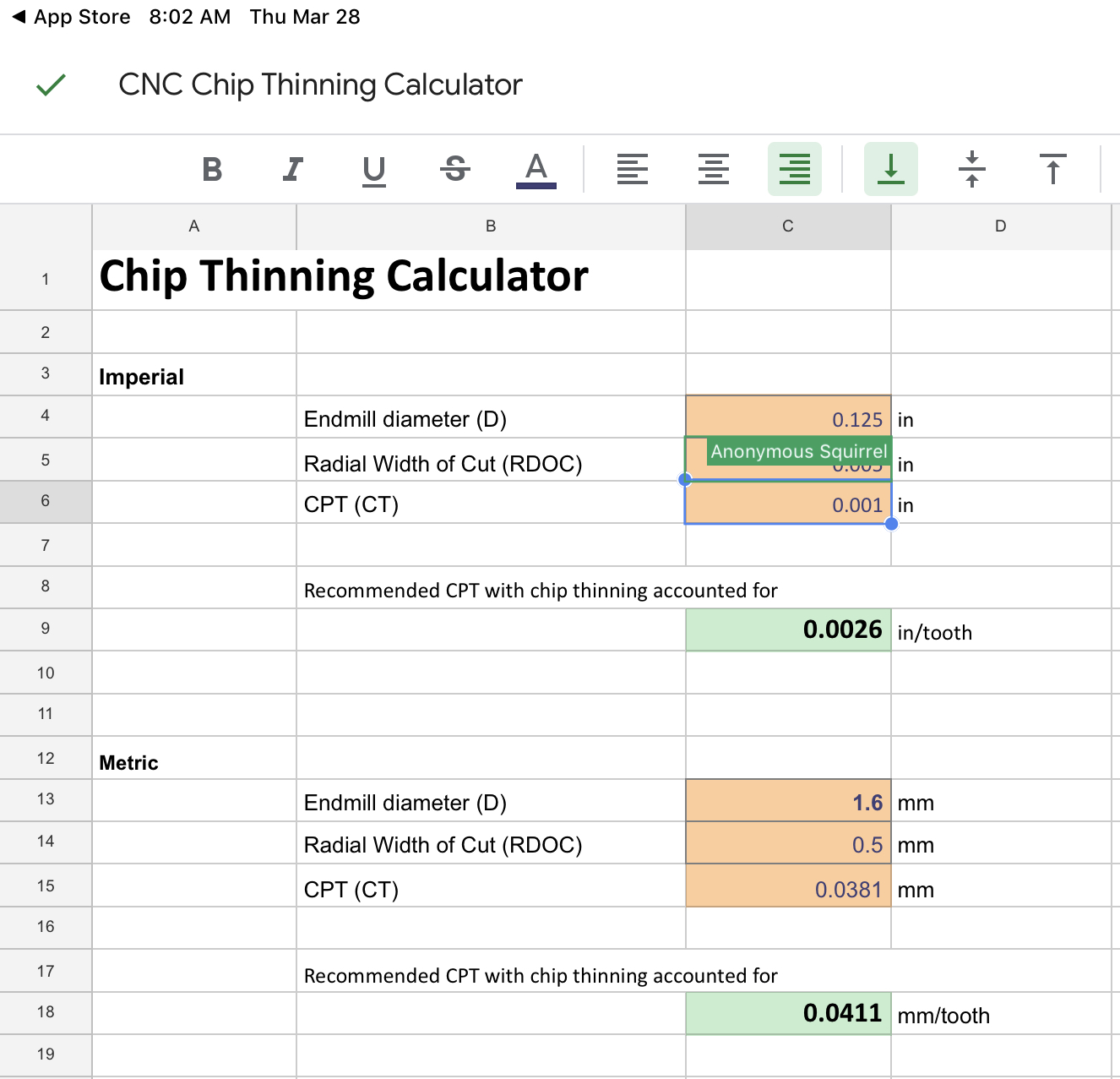

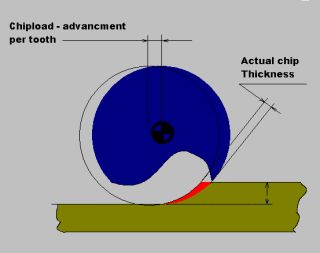

The calculator will give the adjusted feed rate IPT to produce the desired chip thickness. Radial Chip Thinning Factor RCTF Radial chip thinning factor should be implemented with the Radial Depth of Cut Ae is smaller than the cutters radius. ACTF Axial Chip Thinning Factor.

Chip Thinning Straight Milling Calculator Wizard Inch. Result for Straight Milling Radius Chip Thinning Factor RCTF. If youre milling at less than 50 of your cutting tool diameter without leveraging radial chip thinning youre leaving money on the table.

Chip Thinning has already been taken into account for the following series. Radial chip thinning calculator 3. Inches per toothinches per minute conversions 4.

Iscar Tool Advisor New. Recommended by the tools supplier or from our Chip Load Calculator. Actual Feed Per Flute.

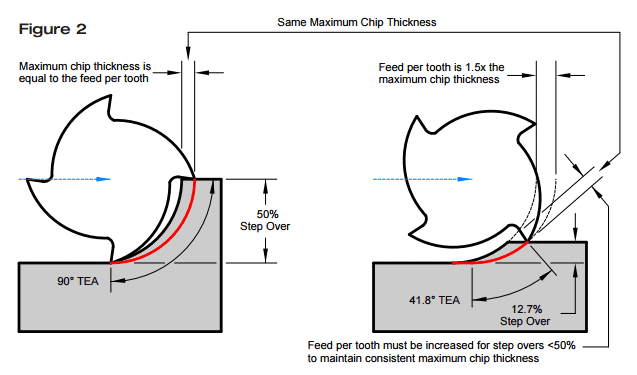

The key is to forget about chip thinning and focus on active chip thickness. Typically reduce feed rate and Axial DOC by 50 when using long reach tools. Use as much of the flute as you can and take a light radial cut.

This website uses CookiesWe use cookies to make our site work. Always use caution and best judgement when applying updated speedsfeeds. 0-50 inches Step 6.

0-1 inch Step 5. Radial Chip Thinning User Guide. Button and see the results below Results.

If you want to take chip thinning into effect take a bigger depth of cut. Chip Thinning is necessary in Trochoidal Milling High Efficiency Machining Dynamic Milling etc tool paths due to a reduced radial stepover. SFM 262 x D x RPM.

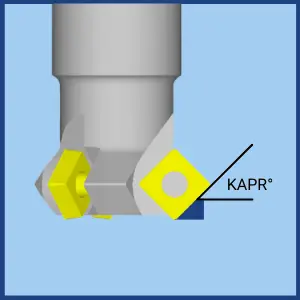

Ball end mill Step over calculation based on reqd surface finish 9. The Chip Thinning factors make sure that the actual Feed per Tooth Fz will maintain the desired Chip Load according to the tool geometry and application settings. Ap Depth Of Cut.

If radial chip thinning could be applied to rough mill-ing huge productivity gains could be had. When using HEM strategy utilizing as much of the cutters LOC is recommended to increase efficiency. These cookies enable core functionality like security network management and accessibility.

Anywhere from 7-10 From there enter in your mfg specs into the said calculators others have mentioned based on material and the calculator will tell you what your chip thinning cpt will be. Chimp or chip load is often confused with chip thickness. Enter the desired chip load IPT into the calculator.

Chip Thinning Calculator Wizard provides you the step-by-step procedures on how to calculate Straight InternalExternal Circular Interpolation. F z A C F T C l. D Ball Diameter.

CPT x Z x RPM IPM. Radial Chip Thinning Calculator. Enter the Radial Width of Cut Radial WOC Radial WOC in inches - Range.

TMR TMS V5 VRX-6. Cl Chip Load. The ratio between the Chip Load Cl and the Feed per Tooth Fz A C F T D D 2 D 2 A p 2.

The programmed feed in this example would be 535 IPM without adjusting for chip Thinning or 1230 IPM by adjusting for Chip Thinning. The chip thickness produced with less than 12 of the diameter in radial contact will be thinner than calculated feed per tooth due to radial chip thinning. Surface Feet Per Minute.

Radial chip thinning calculator for milling. The Adjusted Feedrate Chip Thinning Calculator is available in the tabs above. This calculates the Feed Rate Adjusted for Radial Chip Thinning.

Click here for more information. Fast Feed Milling Quick Tool Selector Guide. Minimize your cycle time and maximize productivity by properly adjusting your programmed feed per tooth.

However most of the chip thinning calculators seem to be based on axial chip thinning. For Making Dies and Molds.

Chip Thinning Calculators And Formulas Machining Doctor

Hem Math With Chip Thinning Factored Carbide 3d Community Site

Chip Thinning Calculators And Formulas Machining Doctor

Chip Thinning Calculators And Formulas Machining Doctor

Chip Thinning Calculators And Formulas Machining Doctor

Chip Thinning Rubbing Lesson 3 F S Email

Chip Thinning Calculator For Windows Tools Emastercam Com

Chip Thickness Archives Page 2 Of 2 Harvey Performance Company

Chip Thinning Calculators And Formulas Machining Doctor

Chip Thinning Calculators And Formulas Machining Doctor

Radial Chip Thinning Calculator For Milling

Chip Thinning Calculator Shapeoko Carbide 3d Community Site

Mastercam 2017 Radial Chip Thinning Factor Cimquest Inc

Chip Thinning And Why You Should Cut More Aggressively

Milling Performance Optimizer Guhring

Anybody Know Of A Good Chip Thinning Calculator R Machinists

Post a Comment for "Radial Chip Thinning Calculator"